The House Printing Telegraph

by Bob Harding

Reprinted from "Crown Jewels of the Wire", December 1990, page 13

A couple of years ago I was fascinated by Ginny Plunkett's story about the

insulators they had found on a early Ohio railroad line in the mid-70's. She

described an odd glass insulator that was fastened to the pole tops and covered

with an iron shell. It was discovered to be an insulator designed by Royal E.

House who invented it for use on his printing telegraph lines.

The Plunkett

family found many pieces before realizing that it truly was an insulator. The

large teal green shards were oddly threaded on the inside as well as the

outside. They found some pieces still laying in parts of the heavily rusted iron

shell. After discovering its true identity they were able to find enough shards

to get a good idea of what the whole insulator looked like.

I made a trip to the

line shortly after I heard the story but was quickly discouraged by the thick

undergrowth. I set aside my thoughts of the House insulator soon afterward.

During the next year or so my interest in threadless hunting increased

greatly. I found myself roaming Ohio, West Virginia and Michigan in search of

abandoned railroads and threadless. In the fall of 1987 Rob Lloyd and I embarked

on a three day search of some lines we had researched. We walked several lines

during that period and for the first two days we found nothing earlier than a

spiral groove (CD 147).

As the noon sun glared down on us that last day we found

another dead end. We decided to checkout one more line before giving up. An hour

later we had finally found the abandoned railroad bed. We followed it for awhile

in the car to get out of town. About a mile or so out of town the country road

followed parallel to the track. The thin 10-yard section of ground between the

bed and the road had recently been plowed. Simultaneously Rob and I both spotted

a glint of aqua from amongst the furrows. Rob jumped out of the car to pick up

the glass. He held up a large piece of glass and mouthed the word "WADE".

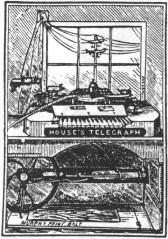

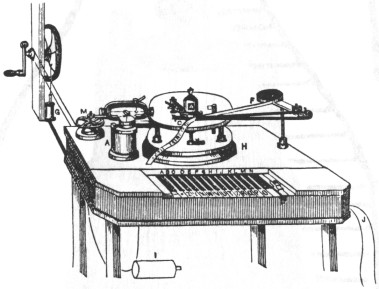

| (Below) One of the improvements in the House Printing Telegraph was a treadle

placed under the instrument which replaced the hand crank. The operator was able

to work the ma chine without an assistant.

|

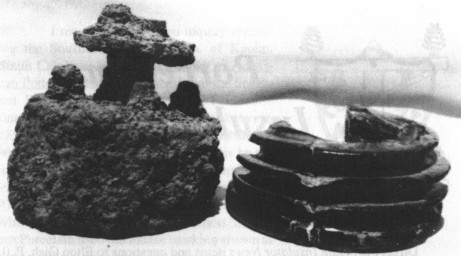

Some of the House insulator pieces found by the Plunkett family.

We walked the small stretch of plowed field and found many more pieces of Wade,

McKee, and unembossed CD 731's. I pulled an olive green piece

from the ground, it was a piece of the "House" insulator. The rest of

the day produced several more pieces of the House insulator in different colors.

At this point we devoted much energy and effort to research as well as walking

the line. As a result, we have found a good deal of pieces in a striking variety

of colors. Bob Roosevelt also accompanied us on some of these trips. He has also

found several "House" pieces on a line in north central Ohio.

Royal E.

House was born in Vermont in 1814. As a young child he moved to Pennsylvania. He

was always interested in science and mechanics. He moved to Buffalo to live with

relatives and study law. Soon law took a back seat to electricity.

Mr. House was

a self-educated man and spent nearly six years perfecting his telegraph

instrument. He was finally granted his patent in 1848 after some dispute since

many of the specifications were in direct competition with Samuel F. B. Morse's

telegraph. When his patent was awarded it was given an earlier date of April

18,1846. He was given an additional patent on December 28, 1852 for improvements

to the telegraph.

The House printing telegraph was unique in the fact that it

used keys similar to those of a piano and printed regular Roman alphabet letters

on a strip of paper. A detailed account on the workings of this instrument can

be found in The Electromagnetic Telegraph by Lawrence Turnbull, M.D., 1853.

(Above) A composing and printing machine were required at every station. The

House composing machine was a three foot wide mahogany frame, two inches in

height and six to ten inches in depth and contained the keyboard. The various

parts of the printing machine are on top of the case. All were powered by a

manual crank. |

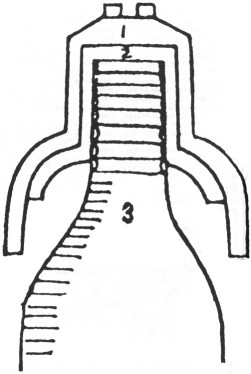

1 - Outer shell of iron on House insulator

2 - Glass liner

3 - Pole

Pieces of the glass liner portion of the insulator

showing the threading on

the inside and outer walls.

Shortly after its inception, lines were constructed across the East. The New

York & Mississippi Valley Printing Telegraph Company contracted lines on

several railroads by 1854. These railroads included the Cleveland & Toledo,

Michigan Southern and Northern Indiana and the "Big Four".

Pieces

have been found on each of the above railroads. Colors include aqua, green aqua,

rootbeer amber, teal-aqua, dark teal green, cobalt, sapphire blue, olive, yellow

olive, jade milk, yellow Depression green. The Plunketts have found several

pieces of the cast iron shell as well as a complete top. Rob Lloyd, Bob

Roosevelt and I have done extensive work with a metal detector along a different line. With literally hundreds of hours of work on

several sections of the line, we still have been unable to find any of the iron

shell. We have been lucky enough to find a couple of the washers that held the line to the top of the insulator. It is my theory that

the insulators were carried off when the line changed over to the Wade

insulators.

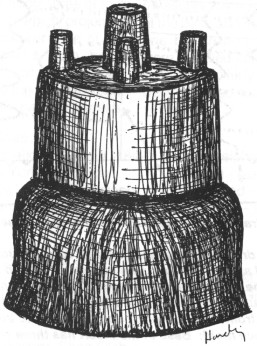

The iron-clad House insulator (Drawing by Bob Harding)

Cut-away drawing and measurements of the House Insulator

At the top of the drawing is the metal washer from a side view and a top

view; The metal sheath had four small posts on the top and one larger middle

post; The inside wall of the metal sheath had only two projections which secured

the threading of the glass insert; Mold line on the glass insert runs from the

base to the dome and would indicate manufacture in a three piece mold; Base of

the insert has three corrugated rings; Inside of the glass insert has threads

that approximate exterior insert threading; Top of glass insert is solid glass

and is about 1/2" in thickness and has a 3/4" button effect in the

middle of the underside.

|

(Left) Top of the iron cap with washer position

on middle post; (right) part

of glass liner

The insulator itself consisted of a glass cap about five inches in diameter,

having a course thread cut inside and out. This glass cap was threaded and

cemented into a bell-shaped iron cap about three or four pounds in weight,

which projected an inch below the lower edge of the glass and protected it from

being broken. The insulator was fitted with much care to the top of the pole and

covered with paint or varnish. The wire was held to the top projec tions by a special washer.

The approved

manner of line installation was with poles 20 to 30 feet in height, set 5 feet

deep, measuring nine inches in diameter at the base and tapering to four and one

half inches at the top. Poles were installed approximately fifteen rods apart.

Thirty Groves batteries were required to carry the current 100 miles.

| Some House Lines: |

|

| New Jersey Magnetic Telegraph (1849) |

Philadelphia-New York City |

| Boston and New York

Telegraph |

Boston - New York City |

| Mississippi Valley Printing Telegraph |

Cleveland - St. Louis |

| Washington Printing Telegraph |

New

York - Washington, D.C. |

Resources:

Digest of Ohio History - pp.240-245

The Electromagnetic Telegraph - Lawrence Turnbull, M.D.

History, Theory and Practice of the Electric Telegraph,

George B. Prescott, 1864

Research and Photos: Elton Gish

Research and Field Work: The Plunkett Family,

Robert Roosevelt, Robert Lloyd, Robert Harding

|